Terbium metal is a rare earth metal with a silvery-gray appearance and unique properties that make it highly valuable for a range of industrial and technological applications. With its wide range of uses, from laser materials to magneto-optic technologies, terbium continues to play an integral role in the development of next-generation products across various industries.

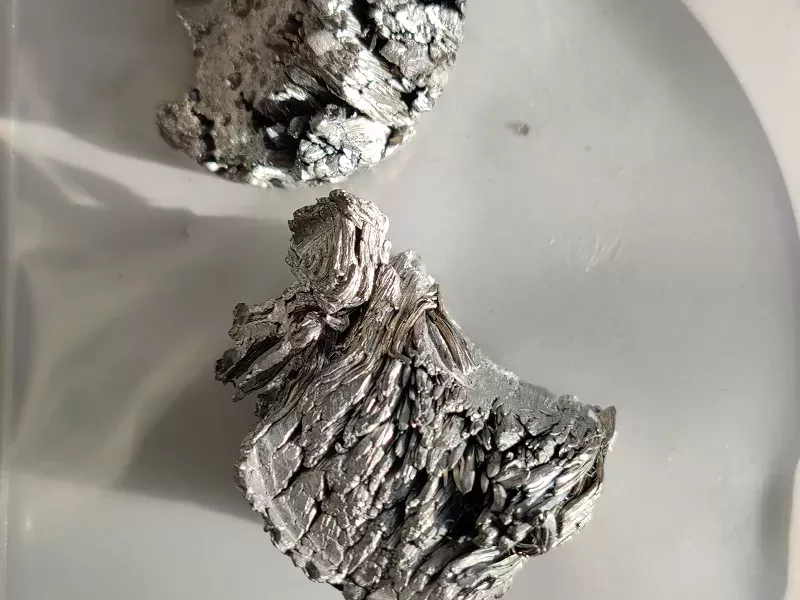

Terbium is produced through two main methods:distillation and reduction. The distillation method results in dendritic terbium pieces with a metallic luster, providing higher purity than the reduction method. In contrast, reduced terbium is dark gray and lacks the metallic luster that distinguishes the distilled version. The purity level o f terbium ingots produced by either method can reach Tb/REM 99.99%, with the distilled versin having superior quality. Terbium metal is known for its slow corrosion at room temperature, although it becomes more susceptible to corrosion when heated.

Terbium’s primary compouds include terbium trioxide (Tb2O3), terbium dioxide (TbO2), terbium fluoride (TbF3), and terbium chloride (TbCl3), which are essential for various applications in electronic and optical devices. Terbium is available in several forms, including foil, sheet, rod, wire, powder, and sputtering targets, all of which mee the highest industry standards. Typically, the purity of terbium powder is REM 99.9%, and its particle sizes are commonly -100mesh and -200mesh.

Terbium Metal

Purity:Tb/REM 99.99% 4N

| CAS No.:7440-27-9 | EINECS No.:231-137-6 | Molecualr Formula:Tb | Molecular Weight:158.925 |

| Melting Point:1356℃ | Boiling Point:3230℃ | Density:8.27 |

Applications

Terbium’s versatility makes it suitable for numerous cutting-edge applications. Below are some if the key uses of this high-performance metal:

1.Laser Materials and High-Temperature Fuel Cells

Sublimed terbium ingots are highly sought after in the production of high-temperature fuel cells and laser materials. Terbium has the property as high melting point and stability. They make it an excellent choice for use in specialized high-energy applications.

2.Magneto-Optic Materials

Terbium is an essential component in the production of magneto-optic materials, which have bulk production capacities. These materials are raw materials for the creation of magneto-optic storage devices, such as Tb-Fe non-crystal films. Such films are increasingly working computer memory elements and storage devices, such s Tb-Fe non-crystal films. Such films are increasingly improving computer memory elements and storage devices. They offer a significant improvement in data storage capacity by up to 10-15times.

3.Faraday Rotatory Glass

Faraday rotatory glass containing terbium is another crucial material, which play an important role in laser technology. Its primary application is in the manufacturing of rotators, isolators and circulators-devices. These equipments control the flow of light within laser systems. Terbium plays a vital role in the performance of these systems, ensuring efficient and stable operation.

4.Terfenol

Terfenol is a remarkable magnetostrictive material made from a combination of terbium, dysprosium, and iron. Initially discovered in the 1970s, Terfenol has gained prominence in a variety of applications, including sonar, fuel injection systems, liquid valve control, wing adjusters for aircraft, and even specialized loudspeakers. The magnetostrictive properties of TerFenol allow it to expand and contract in response to magnetic fields. making in highly effective in applications that require precise movement control.

5.Non-Destructive Testing and Inspection

Terbium wires is valuable for non-destructive testing, particularly in welding inspections for ships and pipelines. This unique properties of terbium allow it to function effectively in detecting flaws and ensuring the integrity of welded joints and metal structures without causing damage. This makes terbium wire a vital tool in industries such as aerospace, shipbuilding, and pipeline construction, where safety and quality control are paramount.

6.Special Alloys

Terbium is also raw material for the creation of high-performance alloys. For example, terbium is a dopant for materials like calcium fluoride,calcium tungstate, and strontium molybdate. Then it creates solid-state devices with improved performance longevity. These alloys are usually raw materials for electronics, photonics, and other high-tech industries.

Why Choose Terbium Metal?

Terbium’s unique properties, such as its ability to form stable compounds and its resistance to corrosion at room temperature, make it an ideal choice for advanced technological applications. Whether you are looking for a material to enhance the performance of lasers, magneto-optic devices, or specialized alloys, terbium provides the high purity and reliability required for cutting-edge industries.

At Zegen Advanced Materials, we offer high-purity terbium metal products, including ingots, powder, foil, and sputtering targets. We focus on delivering top-tier materials to meet the needs of the electronics, telecommunications, aerospace, and medical industries. Our terbium metal products are carefully manufactured using the distillation method to ensure the highest quality and performance.

Terbium is a rare earth element with diverse applications that span from high-temperature fuel cells to advanced optical and laser systems. Its high purity, excellent stability, and magnetic properties make it an essential material for a wide range of industries, including telecommunications, aerospace, electronics, and medicine. Whether you are seeking high-performance alloys, laser materials, or magneto-optic storage solutions, terbium metal is a reliable and valuable resource for modern technological advancements.

Explore our range of high-purity terbium metal products to meet your specific needs. We are committed to providing the highest quality rare earth metals to support your innovative projects.