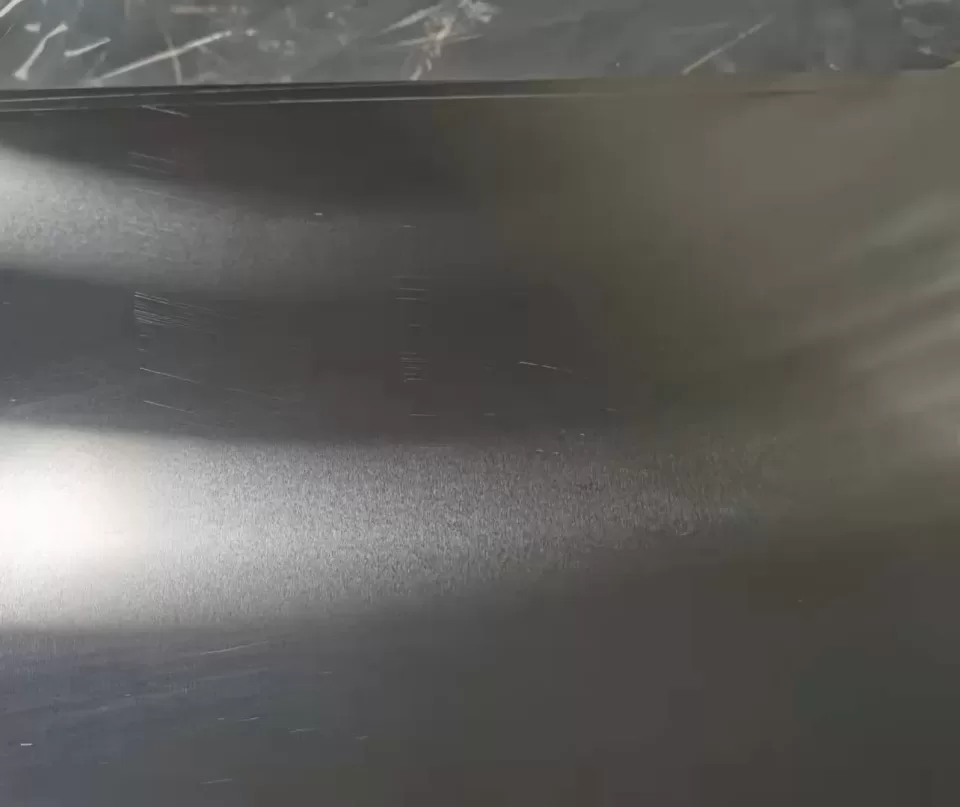

Titanium foil is high-purity, silvery metallic sheet made from titanium, a rare metal known for its excellent corrosion resistance, strength-to-weight ratio, and versatility. Stable in air, titanium is widely used in various industries, from aerospace to electronics, due to its exceptional properties. As an essential material in sputtering target applications, titanium foils play a crucial role in thin film deposition processes for high-tech manufacturing.

Titanium metal is insoluble in water but dissolves in concentrated acids such as hydrofluoric acid, nitric acid, and sulfuric acid, making it suitable for a range of chemical processes and environments.

Titanium Foil

| CAS No.: 7440-32-6 | EINECS No.: 231-142-3 | Molecular Formula: Ti | Molecular Weight: 47.867 |

| Melting Point:1670℃ | Boiling Point:3287℃ | Density: 4.5 |

Foils: Thickness is customizable

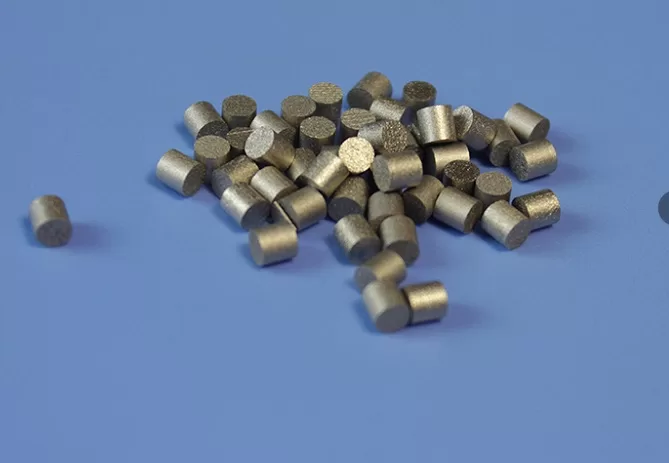

Wires and Slugs: Diameter could be customized

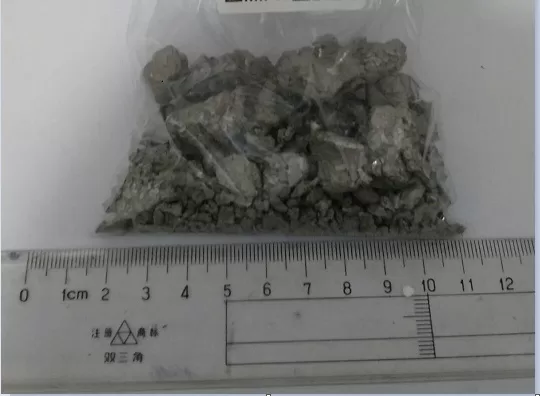

Powders: Particle size is customizable

Applications of Titanium Foils

1.Sputtering Targets for Thin Film Deposition

Titanium foils commonly work as sputtering targets in thin film deposition processes. These films are essential in the production of semiconductors, optical coatings, and photovoltaic cells. Titanium’s unique properties, including its high melting point and corrosion resistance, make it an ideal material for these advanced applications.

2.Aerospace and Automotive Components

Due to its high strength-to-weight ratio and exceptional resistance to corrosion, titanium foil widely works in the aerospace and automotive industries. Titanium components are critical for aircraft, spacecraft, and high-performance vehicles, as they offer durability and reduce overall weight without compromising strength.

3.Medical Implants and Prosthetics

Titanium is biocompatible, meaning it is well-suited for medical implants such as dental implants, joint replacements, and bone fixation devices. Titanium foils is valuable in these applications to create strong, lightweight, and durable medical devices that integrate seamlessly with the humand body.

4.Chemical Processing Equipment

Titanium’s resistance to corrosion in harsh environments makes it ideal for use in chemical processing equipment. Titanium sheets work in heat exchangers, reactors, and other components exposed to agressive chemicals. It can withstand exposure to a wide range of acids, making it particularly valuable in the chemical and petrochemical industries.

5.Electronics and Electrical Conductors

Titanium is raw material for the production of electrical conductors, connectors, and components for high-performance electronic devices. Titanium sheets provide excellent electrical conductivity while maintaining a high level of resistance to corrosion, making them ideal for use in electronic packaging and conductive materials.

6.Research and Development

Titanium sheets are also crucial in scientific research and experimental applications. Their stable, non-reactive properties make them ideal for use in laboratories and research environments, where they are valuable to study material properties, develop new coatings, or create advanced composite materials.