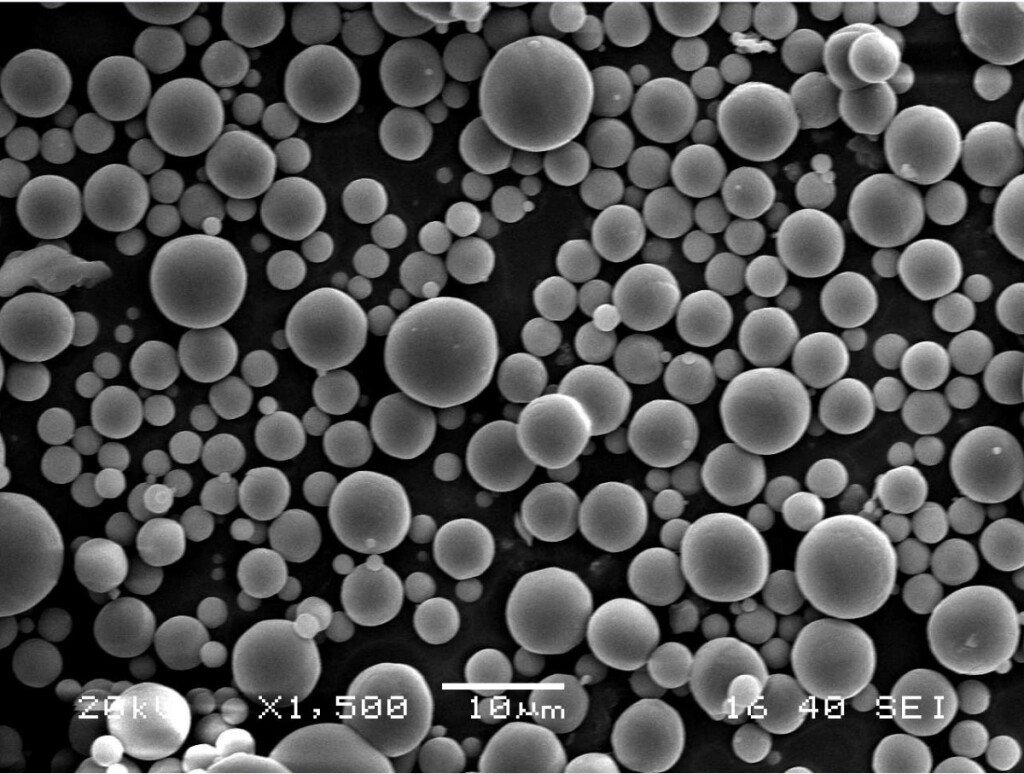

Aluminum oxide nano powder is white fine particles. Renowned for its outstanding thermal stability, extreme hardness, and superior electrical insulation properties, this versatile nanomaterial is insoluble in water, alcohol and ether.

Aluminium oxide nanoparticles are a versatile nanomaterial with remarkable thermal stability, hardness, and electrical insulation properties, making it essential in various high-performance applications across industries. Its ultra-fine particle size and large surface area enhance its effectiveness in ceramics, advanced coatings, electronics, and energy storage, where efficiency, durability, and reliability are crucial.

Aluminum Oxide Nano Powder

| CAS No.:1344-28-1 | EINECS No.:215-691-6 | Molecular Formula:Al2O3 | Molecular Weight:101.96 |

| Melting Point:2045℃ | Boiling Point:2980℃ | Density:3.9 |

Applications

Catalysis & Chemical Processing

Aluminium oxide nano powder is a kind of catalyst and carrier of catalyst, which is main catalyst and carrier in petroleum refining and petrochemical engineering. It is also humectant for air and other gases and acid removal agent for transformer oil and turbine oil.

Advanced Composites & Polymers

Aluminum trioxide is an filling material and sealing material too. It is filling material for chemical fiber, the rubbing agent in rubbing face agent in cosmetics and rubbing agent in toothpaste.

Advanced Ceramics & Technical Ceramics

In advanced ceramics, aluminum oxide nanoparticles are a key component due to its exceptional hardness and thermal stability. It is used to manufacture high-strength ceramic components for applications requiring heat resistance and wear protection, such as in automotive parts, cutting tools, and high-temperature industrial equipment. The fine particle size of Al2O3 nanopowder allows for precise control over material properties, resulting in ceramics with enhanced density and structural integrity.

High-Perforamnce Coatings

In coatings, aluminium oxide nanopowder offers excellent protective qualities. When incorporated into surface coatings, it provides enhanced scratch resistance, thermal stability, and corrosion protection, making it ideal for extending the lifespan of surfaces exposed to harsh environments. Al2O3 nanopowder-based coatings are used in aerospace, marine, and automotive industries, where materials must withstand extreme conditions.

Electronics & Semiconductors

The electronics industry also benefits significantly from aluminium oxide nanoparticles. Its high electrical insulation properties make it valuable for creating insulating layers in microelectronics and as a thermal conductor in heat management applications. In semiconductor manufacturing and electronic packaging, Al2O3 nanopowder provides both structural support and effective thermal regulation, crucial for the performance and longevity of electronic devices.

Energy Storage & Research

In energy storage, aluminum oxide nano powder is efficient for improving battery peformance, especially in lithium-ion batteries. Its high surface area and stability help enhance the electrolyte’s conductivity. It results in faster charging times, improved energy capacity, and longer battery life. Aluminum oxide nano powder also play a part in supercapacitors and fuel cells. It contributes to the development of more efficient energy storage technologies.