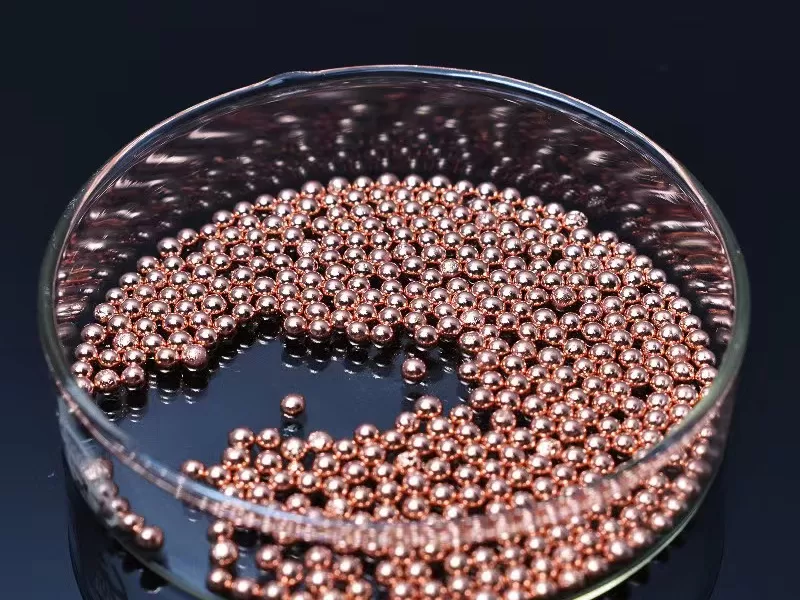

Copper Granules are small,reddish-orange shots of pure copper metal, which is valuable for their excellent thermal and electrical conductivity. These granules are highly versatile and play a crucial role in various industries,including electronics,metallurgy,and material science. Copper granules are produced from high-purity copper and are available in different shapes and sizes to meet specific application requirements. The soft and ductile nature of copper,combined with its superior thermal and elecrical properties,makes it an indispensable material for a range of technological applicaitons. The granules themselves serve as raw material for advanced manufacturing processes or further refined into products such as copper powder, wires,rods and targets.

Chemical and Physical Properties of Copper Granules

| CAS No.:7440-50-8 | EINECS No.:231-159-6 | Molecular Formula:Cu | Molecular Weight:63.55 |

| Melting Point:1083.4 | Boiling Point:2595℃ | Density:8.94 |

Copper Granules are composed of nearly pure copper metal,which has a natural reddish-organe hue.The metal is known for its softness,ductility,and high conductivity, making it a preferred material in numerous industries.

Physical Properties:

- Color:Reddish-orange

- Texture:Soft,ductile,and malleable

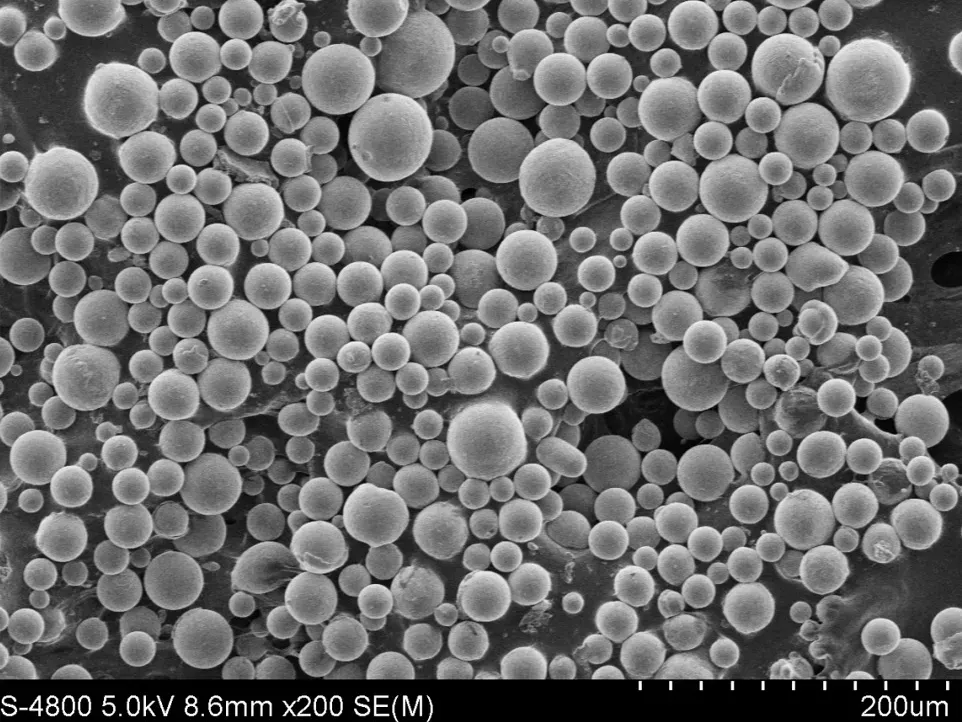

- Shape:Granules are typically small spherical or irregular shapes,though other forms such as plates,rods,and wires are also available.

- Conductivity:High thermal and electrical conductivity,making it an ideal material for use in electrical components and heat exchangers.

- Corrosion Resistance:Copper has inherent corrosion resistance,particularly when exposed to air or moisture,forming a protective patina over time.

Purity Grades:

Copper granules are available in multiple purity grades,each tailored for specifc industrial requirements:

- 99.99% (4N) Pure Copper Granules

- 99.999% (5N) Pure Copper Granules

- 99.9999% (6N)Ultra Pure Copper Granules

The higher the purity grade,the fewer the impurities,ensuring the highest quality performance in demanding applications. For critical applications such as semiconductor manufacturing, electronics,and high-performance wiring,copper with ultra-high purity is often necessary.

Size Specifications:

Copper grains are customizable in size to meet specific manufacturing and industrial needs.Common sizes include:

- 3mm

- 5mm

- 6mm

- 3×3mm

- 6×6mm

These sizes are typically chosen based on the particular application or process,with smaller granules being used for precision processes and larger sizes being used for more robust industrial applications. Additionally,copper granules are available in other shapes such as plates,pieces,wires,rods,and targets,offering fexibility in their use.

Manufacturing Process:

Copper granulars are produced from high-purity copper metal using various methods to achieve the desired particle size and shape. These methods may include mechanical grinding,atomization,or casting. In the atomization process,molten copper is to spray into a chamber where it solidifies into granules as it cools. The size distribution of the granules can carefully get under control during this process to meet specific requirements for different applications.

For applications that require even higher precision,copper granulars may undergo additional treatments,such as:

- Electrolytic refining to further purify the copper,

- Surface treatment to improve performance in high-precision applications such as electronics or semiconductor manufacturing.

Applications

1.Electronic Components

Due to its excellent electrical conductivity,copper is a primary material for the manufacturing of various electronic components. Copper sheets serve as raw material for the production of copper wire,connectors,and other electronic parts. They are essential in the creation of high-performance conductors. They play a part in circuit boards, batteries and motors.

Copper’s ability to efficiently conduct electrical signals makes it a staple in communication equipment,computers,smartphones,and consumer electronics.Copper grains, with their high purity and conductivity, are particularly useful for high-end electronic applications,ensuring efficient performance.

2.Semiconductor and Sputtering Targets

Copper serves to semiconductor manufacturing and thin-film deposition processes,where high purity and consistency are crucial. Copper sheets are for producing sputtering targets and crucibles for thin-film deposition in the production of semiconductor devices and components.

In sputtering,copper is vaporized and then deposited onto substrates to form thin layers used in semiconductor chips,flat-panel displays, photovoltaic cells, and other high-tech applications. The purity of copper shots(such as 99.999% and 99.9999%)enesures that the sputtering process produces clean,consistent films that meet the stringent requirements of semiconductor and optoelectronic industries.

3.Alloy Production

Copper metal serves as an additive in the production of copper alloys. Copper is foten alloyed with other metals like zinc,tin,nickel,and aluminum to improve the material’s strength,corrosion resistance,and other properties. These alloys are important in the manufacture of products like brass,bronze,and copper-nickel alloys,which are to use in applications ranging from industrial machinery to jewelry.

The high purity of copper grains is particularly important in the production of high-performance alloys,ensuring that the final product maintains its integrity and mechanical properties.

4.Heat Exchangers and Thermal Conductivity Components

Copper’s thermal conductivity is another important property that makes it ideal for use in heat exchangers,radiators,and other heat-dissipating components. Copper metal, when processed into larger forms such as plates or rods, are usually raw material for manufacturing components in air conditioning systems,refrefigerators,heat sinks,and thermal management systems for electronics.

In such applications,copper’s excellent thermal conductivity ensures efficient heat transfer,reducing the risk of overheating and improving overall performance. Copper metal often plays a part of the manufacturing process for these thermal components,where the material process into the final product that will work in heat dissipation.

5.Soldering and welding

Copper take effect in soldering and welding because of its excellent ductility and malleability,which allow it to form into wires or rods. Copper wires frequently apply to the production of soldering materials and welding flux for the joining of various metal components in industries like automotive manufacturing,electronics, and metalworking.

Copper-based solder alloys, often mixed with other metals like tin or silver,offer strong joints that are resistant to corrosion and thermal expansion,making them perfect for demanding applications.

6.Metal Coatings and Plating

Copper slugs works in electroplating and coating processes. Copper electroplating is beneficial for a variety of industries to provide corrosion resistance,improve wear resistance,and enhance the appearance of products. The high purity of copper slugs ensures that the plated layer is of superior quality,which is critical in industries such as aerospace,automotive,and consumer electronics.

Copper metal,available in various purities(from 99.99% to 99.9999%),sizes,and forms,are an essential material in numerous industries. Their high electrical and thermal conductivity,combined with their ductility and versatility,make them indispensable for applications ranging from semiconductors and electronic components to heat exchangers,alloy production,welding,and plating. The versatility of copper granules ensures that they remain an essential raw material in the production of high-performance materials and components across multiple sectors. Whether used in manufacturing copper based alloys, sputtering targets,or electronic devices, it is a key building block of modern industry.