Samarium metal (Sm) is a rare earth metal with a silvery-white appearnce and distinct hardness and ductility. It is highly valued for its magnetic properties and wide-ranging industrial applications. Samarium is used in the production of high-performance magnets, nuclear reactors, and optical devices. It has several unique characteristics that make it essential in both high-tech industries and scientific research. This article offers an in-depth look at Samarium’s physical and chemical properties, its production methods, and its key applications.

Samarium is a hard metal that shares similarities with iron in terms of its toughness and rigidity. It is a ductile material, which allows it to be processed into various forms, including powder, foil, rod, sheet, granule, and sputtering targets. While samarium is relatively stable in dry air, it reacts with moisture, forming a layer of oxide on its surface. This oxidation layer helps to prevent further corrosion but can affect the metal’s appearance.

In its powder form, Samarium is soluble in water, yet insoluble in most solvents, and can be highly reactive, even self-igniting under certain condictions. Samarium can also form compounds with non-metallic elements, such as nitride, hydride, boride, and sulfide compounds, which enhance its utility in various chemical processes and reactions.

Samarium Metal

Purity:Sm/REM 99.9% 3N, Particle size:-100mesh, -200mesh

| CAS No.:7440-19-9 | EINECS No.:231-128-7 | Molecular Formula:Sm | Molecular Weight:150.36 |

| Density:7.533 | Melting Point:1072℃ | Boiling Point:1900℃ |

Production of methods for samarium metal

Samarium metal is produced through two primary methods:reduction and distillation.

1.Reduction Method:In the reduction method, Samarium oxide (Sm2O3) is reduced using a suitable reducing agent, such as calcium or lanthanum. This method results in a lower-purity form of Samarium that is more cost-effective for industrial applications, especially where extreme purity is not necessary.

2.Distillation Method:The distillation method, also known as sublimation, involves heating samarium to high temperatures, causing it to vaporize and then condense into a pure, dendritic structure. This process yields a higher-purity product compared to the reduction method, and the resulting dendritic Samarium pieces are ideal for high-precision applications, such as magnet production and nuclear technology.

Forms of Samarium Metal Available

Samarium is available in several forms, each suited for specific industrial needs:

- Samarium Powder:Fine particles used in a variety of applications, including magnet production, alloy formation, and organic reactions.

- Samarium Foil & Sheets: Thin, flexible material ideal for coating, sputtering, or magnetic applications.

- Samarium Rods: Solid, cylindrical forms used in high-performance applications like magnet production and neutron absorption in nuclear reactors.

- Samarium Slugs & Pieces: Used in sputtering targets, reactor applications, and laser materials.

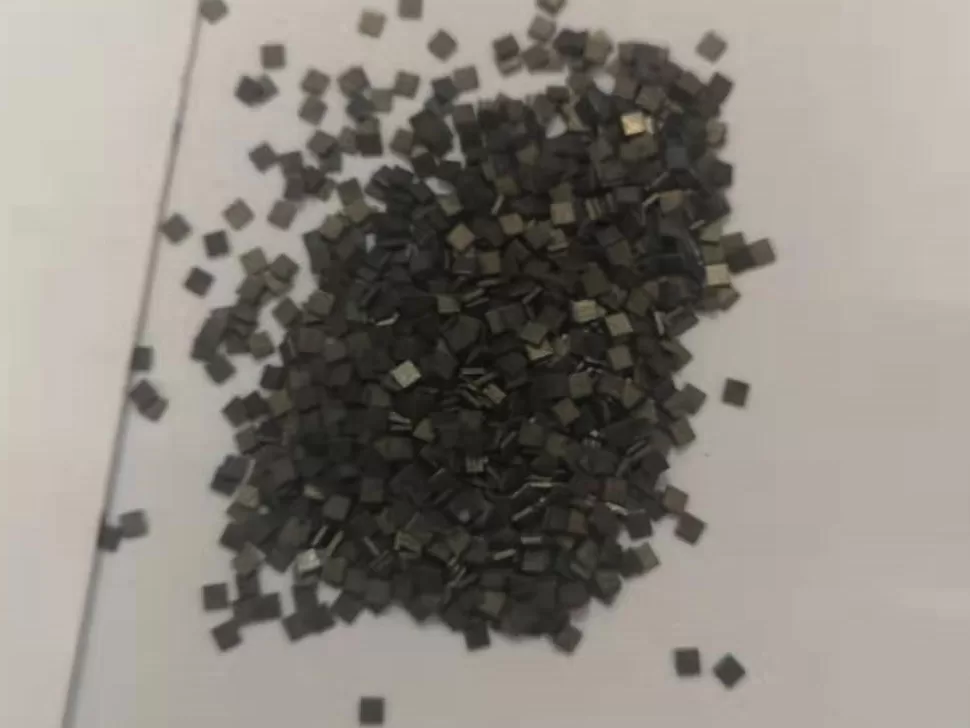

- Samarium Granules & Sputtering Targets: Commonly used for thin film deposition in optical and electronics applications.

Applications

Samarium is indispensable in a variety of high-tech industries and plays a crucial role in advancing scientific and industrial research. Its unique properties make it essential in applicaitons ranging from magnets to nuclear reactors to optical devices.

1.Magnets (Samarium-Cobalt Magnets)

One of the most important use of Samarium is in the production of Samarium-Cobalt magnets, which takes advantage of their exceptional magnetic strength and thermal stability. These magnets play a role in high-performance motors, sensors, aerospace technologies, and medical devices. Due to their resistance to demagnetization and ability to withstand high temperature, Samarium-based magnets are ideal for use in extreme environments.

2.Nuclear Technology

Samarium is also utilized as a neutron absorber in nuclear reactors. In this role, Samarium helps control the fission process, thereby improving the safety and efficiency of reactors. The metal’s ability to capture neutrons is crucial in regulating the rate of nuclear reactions, ensuring that they processed at a controlled pace. Samarium rods serve as control rods and fuel assemblies.

3.Optics and Electronics

Due to its unique optical properties, Samarium is an essential material in the development of phosphors for displays and lasers. Samarium-based phosphors are used in color televisions, LED displays, and laser materials, where their ability to emit bright, stable light makes them ideal for high-quality imaging. Samarium compounds are also employed in the production of infrared absorbing glass, carbon arc lamps, and optical fibers.

4.Research and Development

Samarium compounds frequently get uses in experimental setups and advanced materials for scientific research. The metal’s ability to form stable compounds with various non-metallic elements like nitrogen and boron makes it useful for studying novel materials and reactions. Samarium is also important in the development of superconducting materials, battery technologies, and laser-based systems.

5.Chemical Synthesis

Samarium serve as a catalyst in various organic reactions, especially in the production of Samarium diiodide, which work as a reducttant in organic synthesis. Samarium’s ability to form complexs with other elements makes it an important reagent in organic chemistry and material science.

Samarium is a vital rare earth metal with a wide range of applications in magnet production, nuclear technology, optical devices, and chemical synthesis. Whether in the form of powder, foil, rod, or sputtering targets, Samarium plays a crucial role in industries such as electronics, aerospace, nuclear energy, and research and development. Its high magnetic strength, neutron absorption capabilities, and unique optical properties make Samarium an indispensable material for advanced technological applications.

If you are in need of high-purity Samarium metal or compounds for your industrial or research needs, we offer Samarium powder, slugs, rods, foils, and sputtering targets in various grades and specifications. Contact us today to learn more about how Samarium can support your projects and innovations.