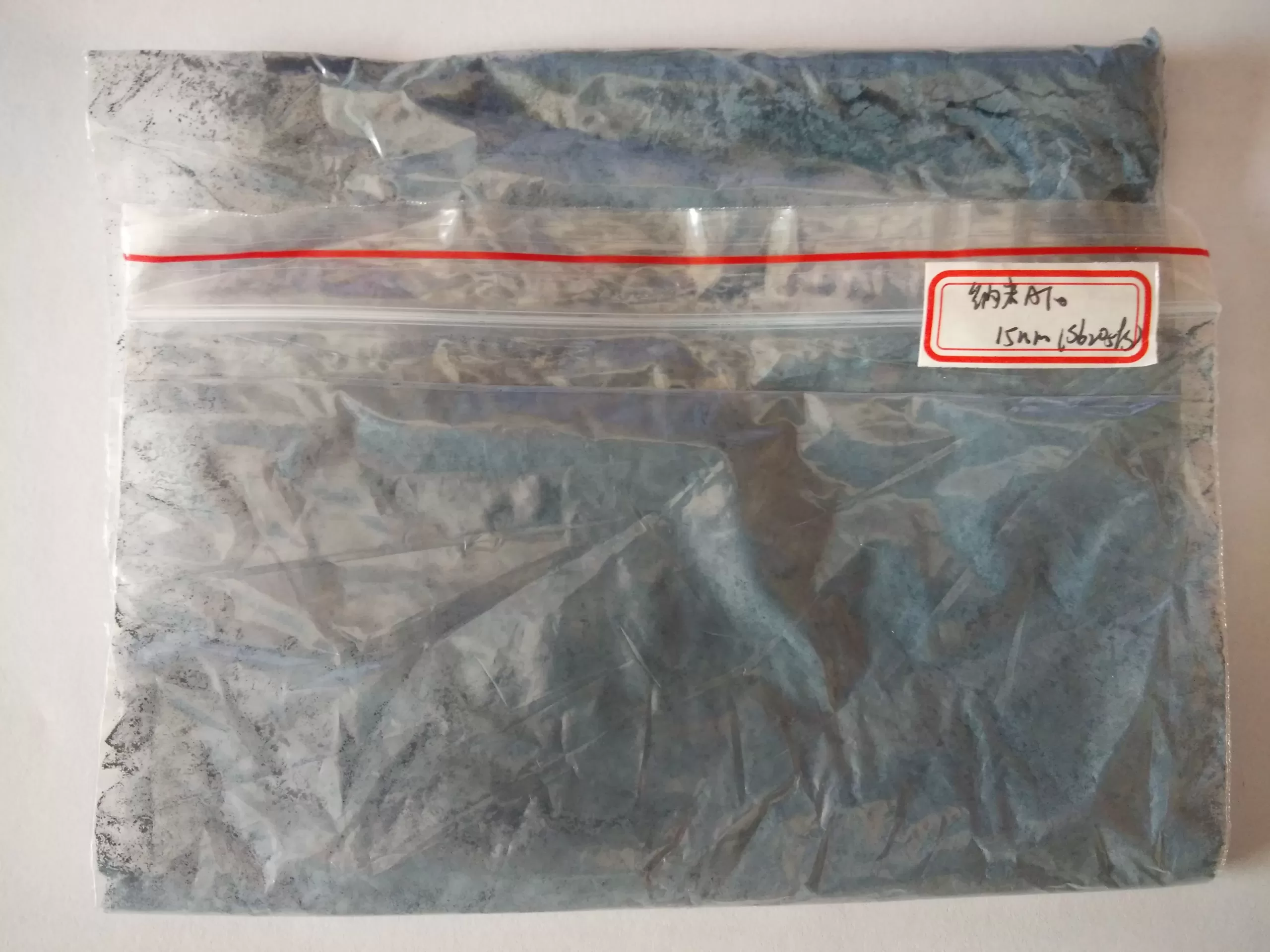

Antimony tin oxide is blue powder and ATO is short for it. Nano ATO powder has high conductivity and property of light-colored transparent, which get great prospects in surface coating applications. Nano ATO owns same property of indium tin oxide and aluminum zinc oxide. They are all raw material for transparent conductive oxide films.

Antimony Tin Oxide

| Ratio:SnO2:Sb2O3=90:10 | Purity:≥99.95% | Specific Surface Area:45-75 | Apparent Density:1.01 |

| Primary Particle Size:10-15nm | Aggregated Particle Size:50-60nm | PH Value:5-11 |

Applications

ATO nano powder mainly apply to antistatic coating. Adding ATO nano powder in polyamide, crylic acid and other matrix resin as conductive coating, choose proper dispersion method to make nano compound transparent antistatic coating.

Adding nano ATO powder when fiber springing, it doesn’t need special dispersing auxiliary due to consistency of inorganic nano ATO (SnO2:Sb2O3) and fiber material.

When adding nano ATO or textile assistant in dyeing processing of raw material as wool top, polyester silk, it finish dyeing and functionalization together.

Antimony tin oxide is additive for antistatic plastics. Nano powder is of small size, which has good consistency to plastic. Further its color is light, processing conductive ATO to plastic additive or plastic conductive master. They are raw material for conductive plastic.

ATO thin film forms with RF sputtering method and the antimony concentration varies 0, 3, 5, 7 wt% . Using MOS-based thin films (ATO thin films can detect low concentration H2 gas with 0.1ppm level. ATO / PbSe composite can serve as efficient counter electrode material for quantum dot-sensitized solar cells.

Nano ATO is usually additive for optics with special functions. ATO / MWNTs composite coating is a highly near-infrared blocking coating for heat conservation windows. Its nanofiber is with superior stability as anode material for Li-ion batteries.